VSM (Value Stream Mapping) cards are an essential optimization tool for managers. They reveal areas of malfunction or waste, and help identify areas for potential improvement. Objective: reduce the time elapsing between an order and its delivery. What is this tool, derived from a tried-and-tested Japanese method: lean management?

Let’s ask the question: you’re looking for a particular product. Three companies are in the running.

- The first can deliver in 30 days;

- The second in 15 days;

- The 3rd in 10 days.

Let’s imagine that the cost is similar in all three cases, and that each of these companies has a good reputation. Is it necessary to ask which one you would choose?

It’s likely that the 3rd company practices lean management, and in particular a tool called VSM – Value Stream Mapping…

What are the goals of Lean management and VSM - Value Stream Mapping?

Reducing waste… It’s a leitmotiv that’s right up there with the times. We find it in the personal sector (as in the reduction of energy or food waste), as well as in the professional sector, with numerous methods having been developed to track down and eliminate what wastes time or resources.

One of the methods developed in this field is what is known as “lean management“. It emerged in Japan, mainly at Toyota, in the 50s, under the inspiration of an in-house engineer, Taiichi Ohno, assisted by Eiji Toyoda, the cousin of Toyota’s founder. From that time on, their aim was to minimize a company’s unprofitable activities.

“Lean management” refers to a set of practices designed to reduce a company’s unprofitable activities.

t is characterized by:

- Eliminating waste: for example, a hundred press kits are produced for a conference attended by 35 journalists.

- The use of just-in-time production: this avoids overproduction and the need to stockpile products when demand may be seasonal. Production rates are therefore adapted to demand.

- First-pass quality: quality checks at each stage of production mean that we can make corrections as we go along, rather than ending up with defective products.

- Standardization: standardized procedures are laid down so that everyone can be as efficient as possible on a given task.

One of the tools used in lean management is a technique for visually representing production or information flows: VSM or Value Stream Mapping.

What is Value Stream Mapping?

VSM – Value Stream Mapping – is based on a precisely codified map.

It is a tool for visually representing all the activities in a production chain, with a view to isolating weak points. The aim is to optimize flows.

The VSM aims to show the flow of materials and information relating to a good or service, from the initial order to delivery to the customer. The map helps to distinguish :

those that generate value

and those perceived as waste

It is both a diagnostic tool (for a past task) and an instrument that can be used to launch a new project. In the first case, analysis of the VSM leads to suggestions for improving productivity. In the second case, a VSM will help to calculate the time needed to produce the product and, if necessary, to optimize / repair this time.

How do you create a VSM?

In a VSM map, the production process of a good or service is approached in its entirety, step by step, with the aim of improving the whole.

Once the initial step has been completed – usually to determine the customer’s exact requirements – the drawing can begin.

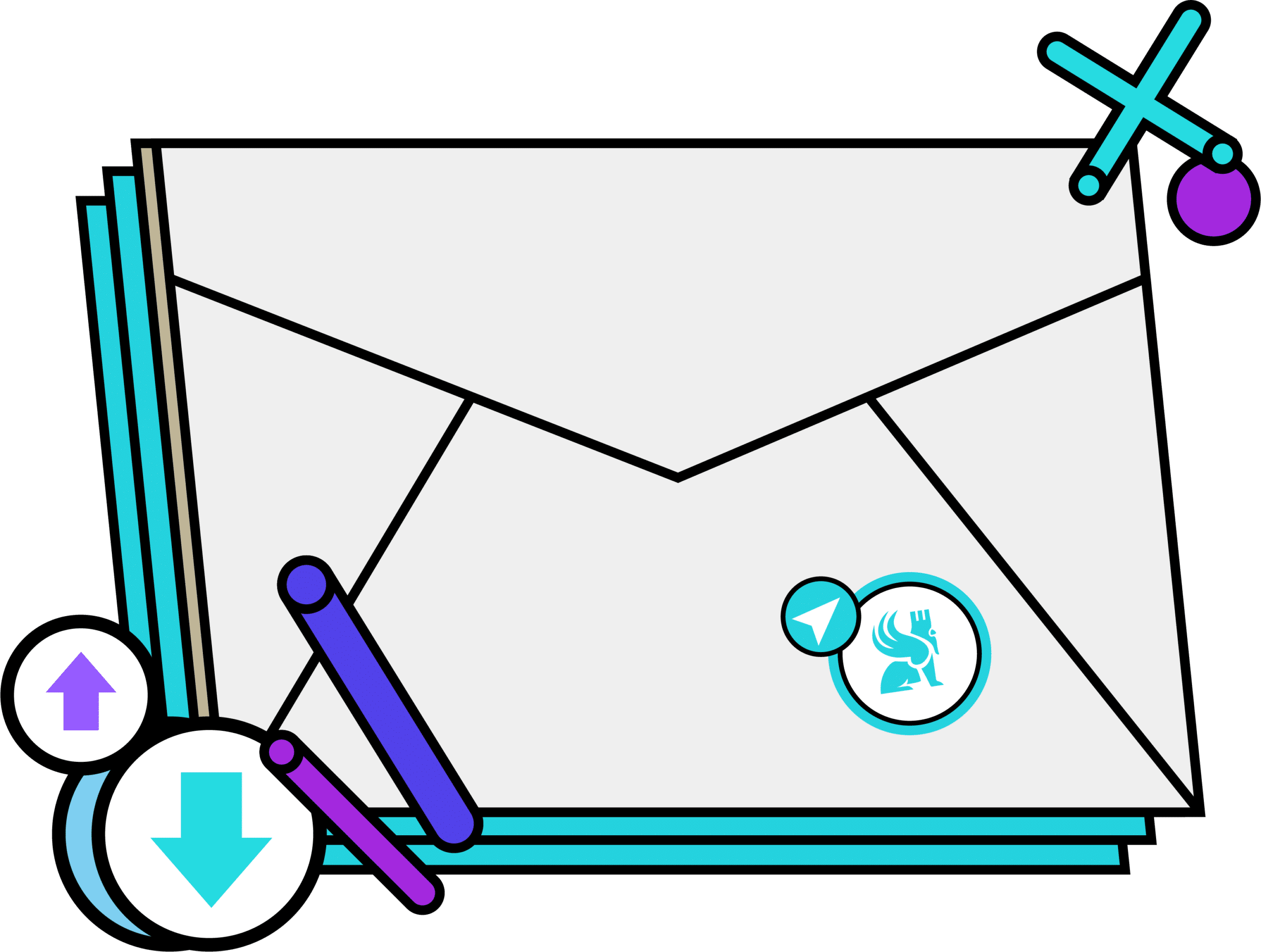

The top section displays the information flow, i.e. the exchange of information between the main links in the chain. It starts with a frame entitled “Customer” on the right, and continues with another frame, further to the left, that of the Company that will provide the service, and also that of the Suppliers who will be involved in the development of the product.

The central part describes the physical flow of processing, the journey from raw materials to the final product. Usually, this is where the reading of a VSM starts, from left to right.

The lower part is the timeline, with the actual time (during which something is accomplished) at the bottom, and the waiting time at the top. This timeline shows the total crossing time, and also the ratio of Value-Added Time to Total Time. This lower section is therefore a major optimization lever.

On the right, when the central part has been completed, there is a block directed towards the customer’s and corresponding to a quality product that has been delivered on time.

VSM - Value Stream Mapping symbols

VSM is based on symbols and pictograms that have become standards. For example:

- An I inside a triangle represents a state of stock (inventory) between two processes.

- A light bulb: an idea,

- A wrench: tools

- and so on.

An essential management tool

From such a map, an executive can determine what obstacles are in the way of the physical flow, and what improvements would be desirable to speed up the flow.

The weak points we seek to track down are usually :

- tasks with zero added value (NVA),

- sources of waste

- bottlenecks.

- etc.

If, for example, the person carrying out quality control is only there on Thursday and Friday, it’s possible that three days are regularly lost. Or perhaps superfluous tasks (unrelated to customer requirements) are being inserted into the production cycle. Or perhaps the volume of manufactured products far exceeds the testing capacity of the corresponding unit.

The VSM – Value Stream Mapping is therefore a major tool that will also help reduce production costs.