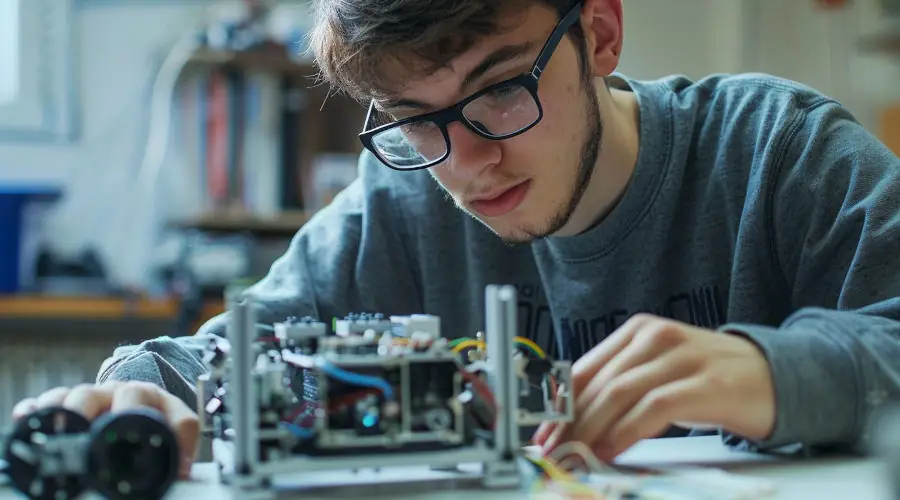

Robotics encompasses everything related to the study, design, and manufacturing of robots: machines capable of acting autonomously without human intervention. Discover everything you need to know about this fascinating field, its connection with artificial intelligence, and how you can train to become an expert!

Since the dawn of the 2020s, artificial intelligence has taken center stage. With the advent of tools like ChatGPT, MidJourney, Udio, and Sora, this technology dazzles with its capability to generate all manner of content: text, images, music, videos…

Yet, this merely signals the onset of a remarkable revolution. In the coming years, AI will transform the world by driving significant advancements in another closely related field: robotics.

Robots will act as the physical embodiment of artificial intelligence, permitting it to interact directly with the physical world by performing actions and manual tasks.

From this point forward, the potential applications will expand, revolutionizing numerous sectors. To fully grasp the magnitude of the impending transformation, we present to you this article detailing all aspects of robotics!

What is Robotics?

At the crossroads of science, engineering, and technology, robotics is a field dedicated to everything concerning automation and robots: machines designed to mimic or substitute human actions.

These machines are capable of executing tasks with greater efficiency and accuracy than humans, rendering them indispensable in sectors like manufacturing.

However, with the rise of artificial intelligence, these machines will soon be equipped to carry out far more complex tasks across an array of industries…

What is a Robot?

A robot is a programmable machine, able to fulfil a task. It has various levels of autonomy, ranging from robots controlled by humans to fully autonomous robots that operate independently.

Certain robots are preprogrammed for specific functions. Thus, they operate in a controlled environment, where they undertake simple and repetitive tasks. For example, this includes mechanical arms used on automotive assembly lines.

To operate a robot remotely, a human operator can utilize wireless networks. The benefit of such machines is their ability to function in the most extreme climatic and geographical conditions.

For example, drones are employed to detect mines on battlefields, enabling demining operations without jeopardizing soldiers’ lives.

Conversely, fully autonomous robots operate independently. They use their sensors to perceive the surrounding environment, then rely on a computer to make optimal decisions based on that data.

The word “robot” originates from the Czech term “robota,” meaning “forced labor.” It made its first appearance in 1920 in the play R.U.R, portraying characters who mass-produce workers devoid of creativity or autonomy.

A robot includes various components. The mechanical part enables it to perform tasks within its designed environment.

For instance, the Mars 2020 Rover has individually motorized wheels crafted from titanium, facilitating navigation across Mars’ challenging terrain.

The electrical components serve to control and power the machinery. Indeed, most robots require an electrical power source, such as a battery.

Similarly, all robots are programmed with computer code. Without instructions, a machine cannot act. Software dictates what actions the robot takes and how it executes them.

What are the Different Components of a Robot?

The control system acts as the robot’s brain. It is programmed to instruct the robot on utilizing its components, akin to how the human brain signals the body to execute specific tasks.

The sensors, meanwhile, equip the robot with stimuli in the form of electrical signals that the controller processes, allowing interaction with the external world.

For example, a camera functions as the robot’s eye, microphones as its ears, and photoresistors respond to light. These features empower robots to assimilate their environment for decision-making.

A robot is not considered complete unless it possesses a mobile chassis. The actuators are the components facilitating this mobility.

These actuators, driven by signals from the control system, coordinate to perform the necessary movement to accomplish the designated task.

Made from materials like metal or rubber, these actuators can be pneumatic or hydraulic. However, most contemporary robots utilize purely electrical systems.

Taking the humanoid robot Atlas from Boston Dynamics as an instance, its initial version was powered by hydraulic actuators, but the company introduced a new electric model in 2024.

For operation, a robot requires energy. Stationary models, such as those in factories, can be connected to a power outlet. On the other hand, mobile robots must be fitted with an internal battery.

Lead-acid batteries are widely used in robotics for their reliability and capacity. Nonetheless, silver-cadmium batteries, which are more compact and costly, are also utilized.

Looking ahead, various energy sources could gain popularity in robotics, including solar energy, hydraulic power, nuclear energy, and even organic waste through methanization!

The History of Robotics

The concept of robotics traces its origins back to antiquity. The ancient Greeks had already merged automation and engineering to create the Antikythera, a handheld mechanism that could predict eclipses.

Several centuries later, Leonardo Da Vinci concocted a mechanical knight, now referred to as the “Leonardo Robot.”

Yet, it wasn’t until the Industrial Revolution that the demand for automation became evident. The first autonomous robots were introduced in 1948 by William Grey Walter.

Subsequently, George Devol invented the first industrial robot arm, Unimate, which was deployed in General Motors factories beginning in 1959.

Another milestone was the creation of the first AI robot, Shakey, in 1972 by the Stanford Research Institute. It was equipped with cameras and sensors to gather data about its surroundings.

This innovation prompted further exploration into robots’ capability to process human emotions. In the late 1990s, Dr. Cynthia Breazeal from MIT introduced Kismet, a robot head expressive of facial emotions.

In 2012, the advancement of Deep Learning propelled robotics forward. Today, numerous entities strive to merge robotics and artificial intelligence to fabricate versatile humanoids capable of executing any manual labor…

The Different Categories of Robotics

There are varied types of robots, leading the robotics industry to segment into multiple categories. Here are the principal ones.

Industrial robots are perhaps the most recognizable, employed to automate tasks in manufacturing settings such as factories and warehouses.

Equipped with at least one robotic arm, they can manipulate heavy objects while moving swiftly and accurately, boosting productivity on assembly lines.

Conversely, medical robots support healthcare professionals in diverse capacities. With the aid of sensors and AI, they navigate facilities, interact with humans, and execute precise maneuvers.

These robots are even capable of conversing with humans, providing emotional support and maintaining social contacts for those in isolation.

Another innovative development is microbots, or micro-robots, so small they barely reach a millimeter in size. They are designed to monitor and treat illnesses.

In the agricultural sector, robots tackle labor-intensive and repetitive tasks, enabling farmers to better allocate their time and resources. They monitor crops and assist with harvesting in greenhouses.

The term Cobot, short for collaborative robots, refers to robots engineered to work alongside humans.

They prioritize safety through sensors that detect their surroundings, performing slow movements and ceasing operation when obstructed.

Mostly, these robots carry out simple tasks, allowing humans to concentrate on more complicated endeavors.

Humanoid robots, resembling humans or mimicking human behavior via artificial intelligence, can carry objects, jump, or even run.

They even replicate our facial expressions and emotions. Among the most notable examples are Boston Dynamics’ Atlas, Figure 01, or Tesla Optimus.

This branch of robotics is experiencing rapid growth, as advancements in mechanics and artificial intelligence enable the creation of increasingly lifelike humanoids.

The journey is just beginning. In the years ahead, these robots will become increasingly indistinguishable from humans…

Which Sectors Use Robotics?

Robotics finds applications in a broad array of sectors. In manufacturing, industrial robots can assemble products, sort items, and even paint them. They also repair and maintain machinery within factories.

In healthcare, they transport medical supplies, conduct surgical procedures, and provide emotional support to patients.

Robots also offer companionship to children with disorders, or act as therapeutic aides for individuals with dementia.

They play crucial roles in rescue missions, especially in saving individuals from drowning during floods or combating fires in scenarios too hazardous for human firefighters.

Within households, the general populace already employs robotic lawnmowers and vacuum cleaners. By 2050, according to Elon Musk, everyone will possess a humanoid robot at home to manage all domestic chores and beyond…

Many Advantages... But Also Significant Risks

Robotics brings a multitude of benefits. Firstly, robots can execute movements with greater precision than humans.

Additionally, they can work more consistently than humans, without ever slowing down or growing tired. This leads to an enhancement in productivity and quality.

Their deployment in environments too hazardous for humans also provides a safety advantage, protecting workers from harm.

For businesses, investing in a robot might prove more economical than hiring an employee. Nonetheless, the specter of automation poses a risk of unprecedented unemployment levels.

Moreover, robots possess a more constrained capacity for creativity and problem-solving compared to humans, potentially leading to drawbacks.

Another concern is cyberattacks targeting robots, which could compromise sensitive data if they are connected to the internet of things.

In the event of equipment failure, production could be halted, resulting in financial losses. It’s also crucial to remember that the extraction of raw materials for robot fabrication can have a significant environmental impact…

The Future of Robotics

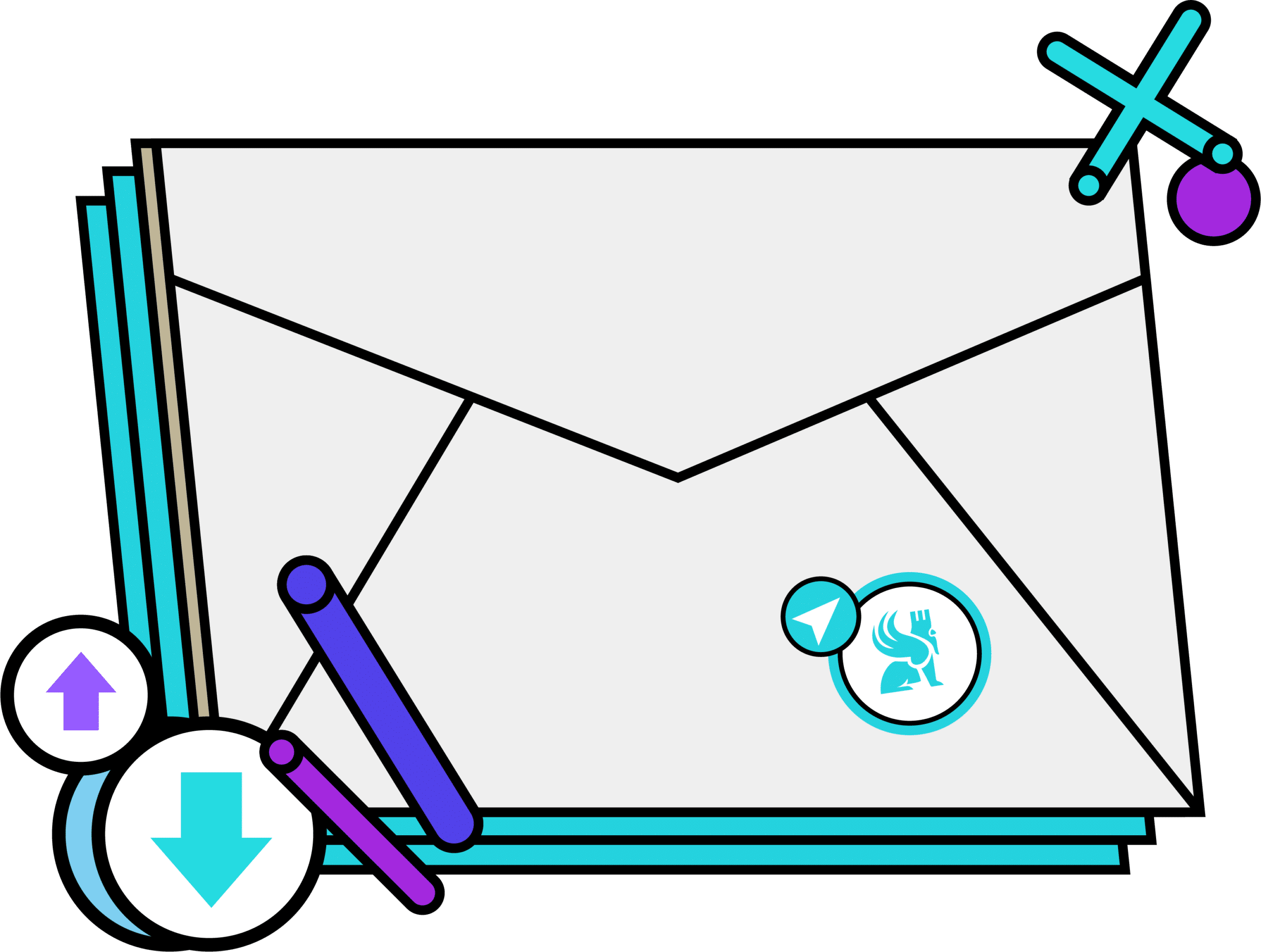

Artificial intelligence is advancing swiftly and is poised to have a considerable impact on the future of robotics. In manufacturing, the integration of these technologies will facilitate the creation of digital twins and the development of simulations to enhance corporate workflows.

Moreover, AI will further extend the autonomy of robots. For instance, drones will be capable of delivering packages without human intervention, while tools like ChatGPT will empower them to engage in conversations.

Humanoid robots are evolving to become more human-like, with the ability to comprehend and respond to emotions. They will increasingly become integral and useful across a range of sectors, including customer service, manufacturing, logistics, and healthcare.

While many worry that this surge in robotics may lead to significant job displacements, this technology could instead redefine the nature of human labor.

Repetitive tasks will be entirely delegated to robots, allowing humans to tackle more complex challenges. Nevertheless, adjusting to the presence of robots will be essential as robotics continues to flourish!

Conclusion

Robotics, an industry on the cusp of its golden age. Robotics has existed for numerous decades, but is on the brink of a pivotal breakthrough courtesy of artificial intelligence.

Now capable of cognition, understanding their environment, robots will gain complete autonomy and assist humans in carrying out the most perilous or monotonous manual tasks.

We stand at the threshold of a new epoch, with the onset of the commercial rollout of general-use humanoid robots like Tesla Optimus, Figure 01, or 1X Eve poised to revolutionize our world. And you can play a part in this revolution!

To pursue a career in robotics, consider choosing DataScientest. Our remote training programs will equip you with expertise in Data Science, Machine Learning, and artificial intelligence: the core technologies underpinning modern robotics.

These skills will empower you to contribute to the creation of intelligent robots, in terms of both hardware and software. Thus, you can embark on a future-focused career path.

Our courses, accessible online through BootCamp, apprenticeship, or continuous learning, culminate in a recognized certification. You can fund your training via the Personal Training Account (CPF), as our institution is accredited by the state. Explore DataScientest!

You now have a comprehensive understanding of robotics. For additional insights on this topic, delve into our article on artificial intelligence and our piece dedicated to automation!